From more meat to less waste: How food companies use AI

Published in Business News

At a Cargill slaughterhouse in Texas, AI-equipped cameras scan every cattle carcass and let workers know when they’re literally leaving too much meat on the bone.

Even a 1% improvement in yield could produce millions more pounds of meat a year thanks to artificial intelligence.

“I do believe it’s the most transformative technology or innovation of my lifetime,” Cargill CEO Brian Sikes said at an event in Iowa last month. “There will be companies that embrace this and those that don’t, and I think we’ll look back in a decade, and those that don’t embrace the opportunities that it brings will be in the graveyard.”

Minnetonka-based Cargill is one of many food companies enthusiastically embracing artificial intelligence, adopting the technology to make innovation, supply chains, marketing and manufacturing more efficient.

The rapid uptake of AI across the economy has many worried about the other side of increased efficiency — lost jobs — especially as layoffs ripple through tech companies. But the food industry still needs plenty of people, industry leaders say.

“If you get replaced, it will be by somebody that’s willing to engage with the technology,” Sikes said.

General Mills has been investing heavily in recent years to get ahead of the competition on AI, CEO Jeff Harmening said: “There’s no prize for second place.”

For the cereal-maker, AI is about building new capabilities that help the company “stay on top of evolving consumer behaviors and external trends,” Harmening said during the company’s October investor day at its Golden Valley HQ.

Here are a few more examples of how AI is changing the business of food.

If companies can accurately predict how much food they will sell, they will make just enough to meet that demand. That avoids both empty shelves and food waste.

This demand forecasting is saving money in General Mills’ supply chain “and bringing a better rhythm of performance,” said Paul Gallagher, chief supply chain officer at General Mills.

“We’re seeing that in lower costs. We’re also seeing it in less waste and ultimately better customer service,” he said.

Demand forecasting has historically taken immense amounts of time and staff resources. Gallagher said AI has “reduced the time that people are spending in the system by over 50%.” And he even sees a way to increase that to 75%.

AI might not make the process 100% accurate, but it’s a massive step-up for an industry selling perishable goods.

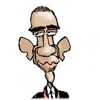

“There’s a lot of human error involved,” said Brett Brohl, a managing partner of Bread and Butter Ventures and longtime food-tech investor. “Will AI ever get it exactly right? No, but it will get closer.”

Brohl said one of the most obvious ways to use AI to improve the food system is through traceability.

Tradeverifyd, a company Bread and Butter has invested in, tracks environmental and geopolitical risks in a supply chain. It scans a firm’s messy and often global web of suppliers for threats like drought in coffee-growing regions or wars disrupting trade routes.

“Who’s supplying your supplier?” Brohl said. “It’s the perfect use case for an AI solution, for something that can come in and do it significantly better, faster, much more real-time than human beings can do.”

On the other end of the supply chain, General Mills and an undisclosed major retailer have connected their systems to optimize deliveries with AI.

“On top of the opportunity to drive millions of dollars out of that supply chain, it’s taken out, to date, 15,000 tons of carbon because we have less trucks on the road,” Gallagher said. “What used to take us 18 hours to go through those orders and optimize those orders to get truckloads is now taking us less than 30 minutes.”

Brohl said AI will “make people more efficient and effective” rather than replace them in the near-term.

“Nobody’s really embedded AI into the process or taken humans completely out,” he said. “We’re not there. There’s a variety of reasons for that, and I actually don’t think we’ll be there for quite some time, especially in the food system.”

No more repeated trips to the printer for a package design no one will see: With generative AI, companies are virtually prototyping.

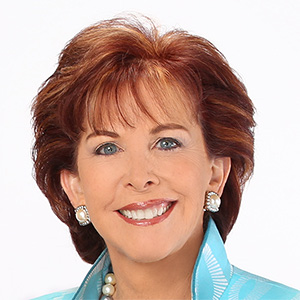

“This includes using visualization tools to create and iterate literally hundreds of visual prototypes so that we can understand consumer desirability before we even make one physical prototype,“ said Lanette Shaffer Werner, chief innovation, technical and quality officer at General Mills.

AI is also weighing in on the designs with bots called “digital personas” while also running consumer surveys around the clock, she said.

On the marketing side, General Mills recently founded Studio G to do more creative work internally, like trying out some AI-generated Pillsbury Doughboy ideas.

“We expect these and other AI-based tools will help us continue to optimize our media investments going forward,” said Dana McNabb, head of North America retail and pet at General Mills.

Coca-Cola is back with another AI-generated holiday ad this year. The company’s head of generative AI, Pratik Thakar, promised it will avoid the uncanny valley unlike last year’s spots.

“The genie is out of the bottle,” he said in an interview with The Hollywood Reporter, “and you’re not going to put it back in.”

©2025 The Minnesota Star Tribune. Visit at startribune.com. Distributed by Tribune Content Agency, LLC.

Comments